Electronics

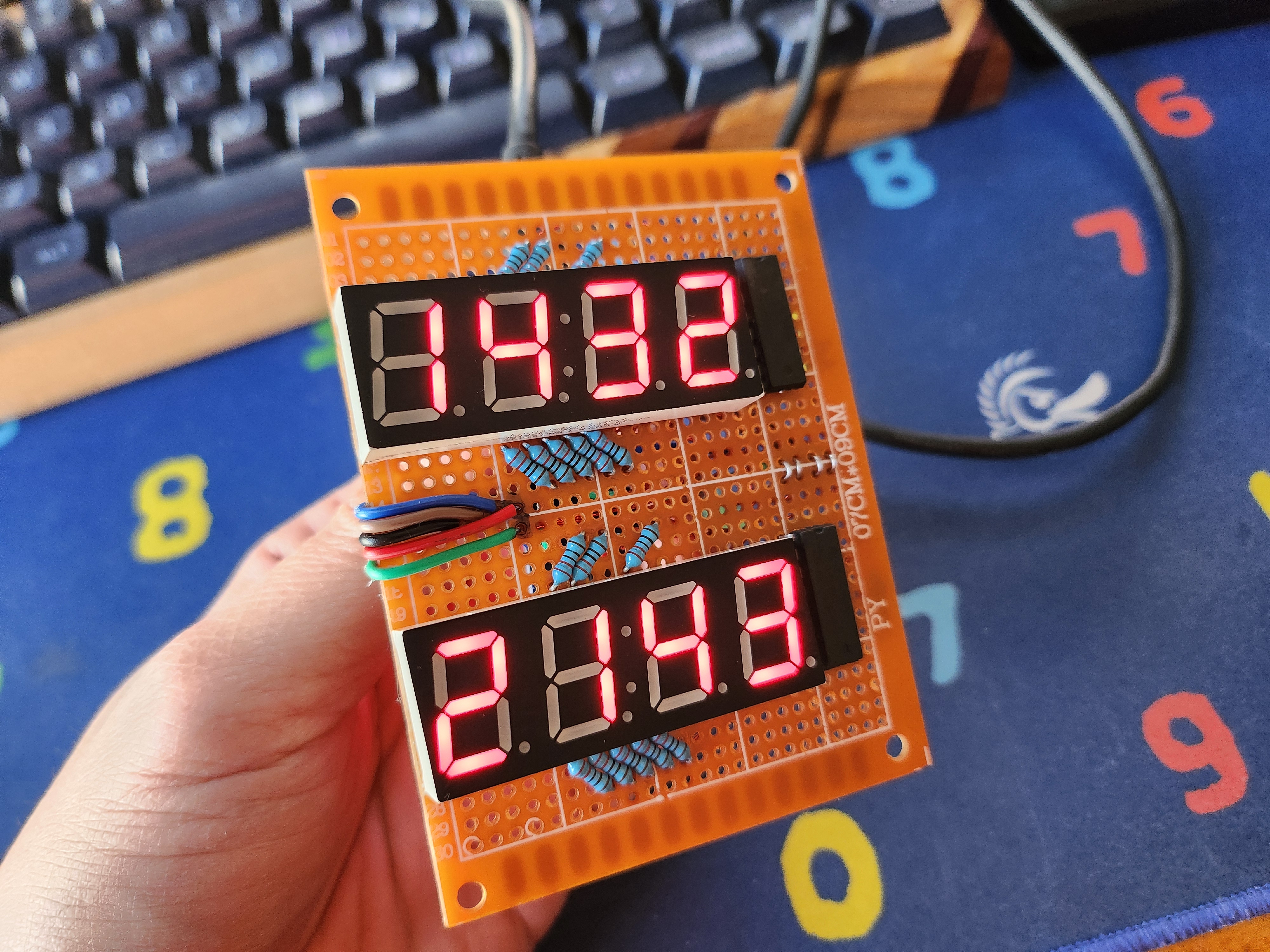

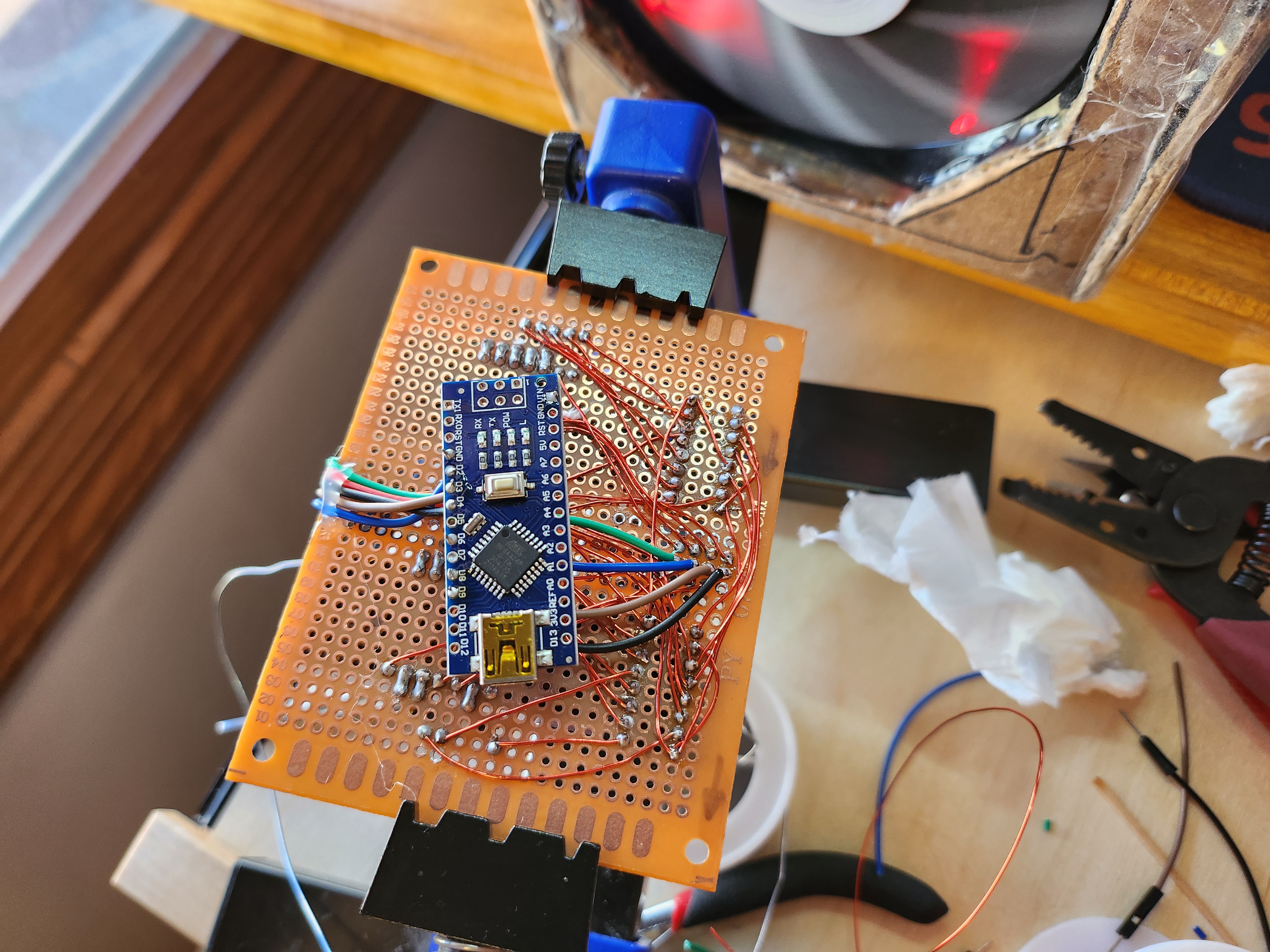

I’m working on a CPU/GPU readout for my PC. So far it’s been a week of on-and-off soldering and handwiring and tinkering with this Arduino Nano clone, seven segment displays, and shift registers, for something one could probably find on Aliexpress for less than $10.

I mean, that’s not the point though. Neither is the coding part or the learning how electronics work, really. On paper this is pretty much a waste of time and money. I enjoy it though. It’s a great intersection between my love of technology and my love of craft. A successful solder joint gives me the same feeling as a good plane shaving. In this case though, it’s an additive process as opposed to subtractive. Instead of carving material off, you’re adding metal and silicon to your project, and you can feel the board getting physically heavier as you go along.

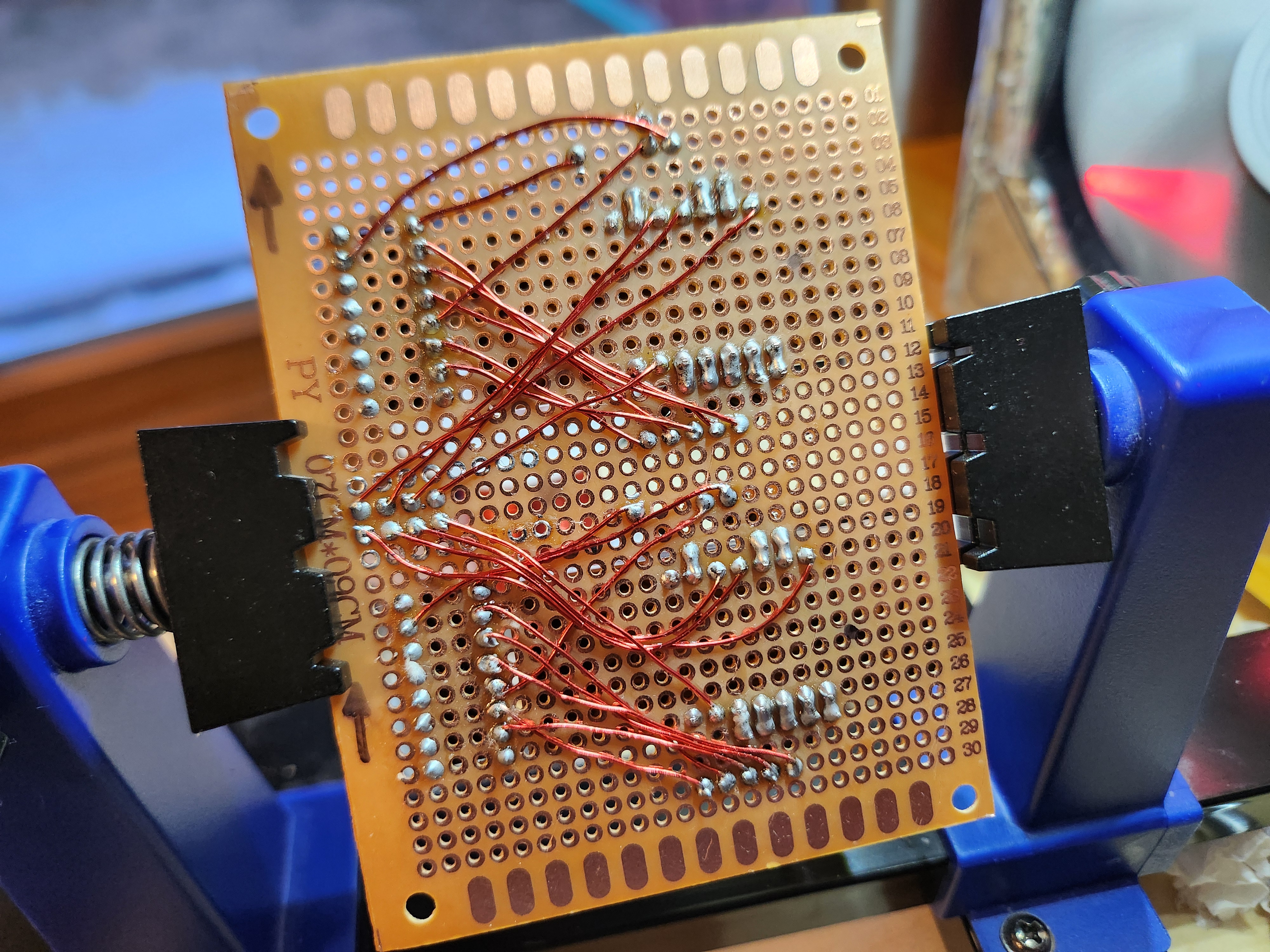

The handwiring bit is a carryover from my time spent building keyboards from scratch. For some reason I’ve come to enjoy working with magnet wire, thanks to my custom tool, which is actually just an Xacto knife with half the blade snapped off. I use it to carefully scrape off the enamel insulation. I find this better than working with plastic/rubber insulated wire, which tends to melt, shrink, crumble, etc. Also, the negligible thickness of the insulation means the wires take up way less space, so I can cross wires over a lot more before having to resort to creative wire routing.

Mostly, the shiny red wire is pretty and reminds me of a nervous system.

The hardware is all set up and appears to be working OK (with no magical smoke), but the digits are not showing up in order.